HYT Technologies Part 2: Functioning and constraints

A water watch? The human adventure at the origin of the development of the HYT H1 materialized what seemed only possible in theoretical physics. Here are the technical explanations.

The functional principles of the fluid module posed so many problems that it required the creation of unheard-of processes and technologies, particularly when it came to producing the prototype and industrializing the watch’s overall production. In order to get a better grasp of its functioning we are presenting the remarkable list containing of all its constraints. We are also providing the names of the men who made possible what originally was a quasi-philosophical intention.

“The idea behind ‘Back to Clepsydre’ is a real quantum leap, even more dizzying than a return to the watchmaking techniques of the 17th and 18th centuries. Since numerous components of the fluid module offer limited reliability in their close interactions, tolerance zones are less controllable than those in the traditional crafts of watchmaking.

Furthermore, these tolerance zones tally up. This type of complexity has nothing to do with traditional quality control as it is understood in watchmaking”. Vuillamoz makes it clear: there are quite a number of challenges to be met and we can’t apply good practices because no one has produced a watch like this before.

Functioning principles of the fluid module

Before evaluating the immensity of the physical co-contracting that had to be mastered to make the fluid indicator of the HYT reliable, it is vital to understand its functioning. The fluid module is composed of a glass capillary that links two supple metallic reservoirs filled with two immiscible liquids of which one is colored and the other transparent. When one of the reservoirs is pressed, the compressed liquid moves into the capillary thus creating a display interface instead of a junction between the colorful and the colorless transparent zones.

The display system inevitably goes back to its original state when the compression is applied to the first reservoir each time the fluid indicator reaches 6 o’clock. The liquid then makes an inverse turn lasting for approximately one minute before restarting the 12-hour compression cycle.

As liquid can expand with temperature variations, a thermal compensator – an intermediary device – had to be integrated in order to avoid the unwanted effects of this physical phenomenon. In fact, when expanded, the liquid can only be moved in the capillary and can thus compromise the precision of the time displayed. The thermal compensator (3) functions like a loophole and thus corrects the position of the liquid in case of temperature variation.

Problematic and industrialization

The development of the HYT fluid module has been carried out within the frame of early-stage research and innovation. The approach is quasi-empirical; observe, design, apply and, if decisive, develop it and make it reliable.

The diverse problems that the development of the HYT fluid module posed had to be reduced and broken down. Furthermore, interaction between crafts mastered by engineers and those mastered by watchmakers had to be found.

The first challenge that was met was the energetic balance of the fluid module. The question was how to move the liquid with the low amount of energy that a mechanical watch movement can produce. Since the system functions as a spring, the energy is restored every 12-hour cycle. Thus the energy is not lost since there is no need to “press” twice and thus lose the double energy produced by the mechanical movement. This is the problem that dictated the dimension of all the pieces in the fluid module. Then came the task of managing the movement of the two liquids with precision. The balance between the fluids is particularly critical. As a matter of fact, the liquids have to be immiscible and offer as less affinity as possible with the capillary’s glass wall. Yet, a polar liquid that can push a glass wall is inclined to have affinities with the other liquid. The capillary and the two liquids have to push against each other and the coloring – apart from being miscible with one of the liquids – must never be blended with the second liquid.

Therefore, to obtain the good composition of the liquids and the coloring agent, a number of tests were carried out to make the initially incompatible cohabitate.

This “fluid management” required important developments that allowed the control of the speed and the regulation of the flux. The fluid channeling thus went through the creation of different diameter zones so that its flux might be regulated at each step such as liquid filling, winding, functioning, and so on. There is also the thermal compensator that allows managing differences in temperature and thus prevents liquid expansion. It was after repeatedly adjusting the assembling of diverse elements of the fluid module that it was possible to avoid losing the liquids. As a comparison, the level of water resistance of the fluid module is 10,000 times more than a 100-meter water resistant watch.

A bridge between physics and watchmaking

Once the main problems were identified and solved, they had to be coordinated. Procedures had to be implemented to allow the engineers’ demands to cohabitate with those of the watchmakers.

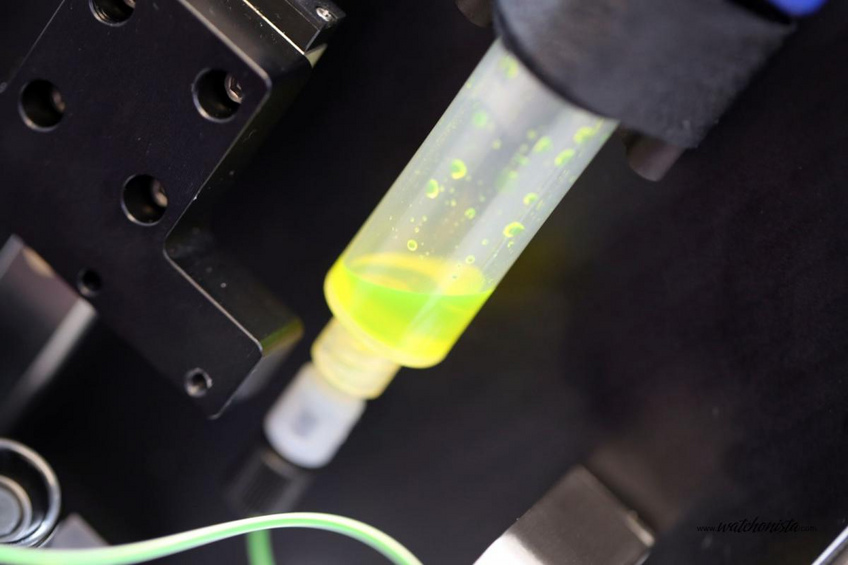

As a result, watch production actors implemented part of the engineers’ knowledge in order to synchronize both mechanical and fluid time. A number of machines were specifically created; for example, there was an apparatus which dealt with the sensitive and delicate step of filling the watch with liquid. Another example would be the gauging tools that helped measure the precision of different elements under extremely low tolerances. The glass capillary and the bellows have precise dimensions, give or take a few microns. Finally, a cycling tool was needed to simulate each fluid module’s functioning before being put on the mechanical movement.

A HYT watch is thus much more than a movement and an additional module. It is the result of an alliance between watchmaking and physics under its most varied forms such as micromechanics and fluid dynamics. With the H1 and the more recent H2, HYT has entered new territory in time display while creating new technologies and making them reliable.