Vaucher Manufacture increases power reserve sixfold: revolutionary!

Named after its inventor, the Genequand mechanical regulator was launched on September 15 2014 at the CSEM in Neuchâtel. It takes up the same space in a watch caliber and features no balance spring or chronometric loss.

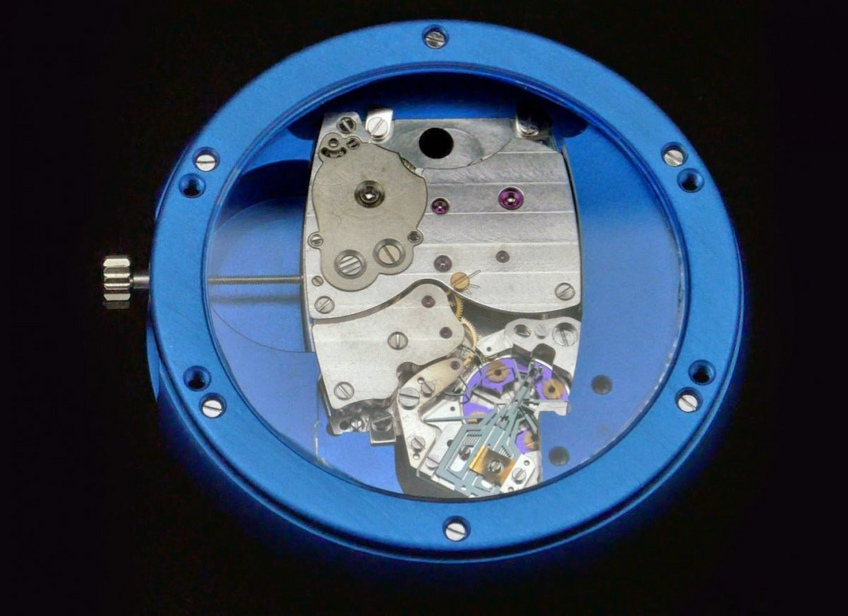

Until that famous September 15, the unit of measurement of mechanical movements’ power reserve was either hours or days. Henceforth, it will go as far as a month. After ten years of research in collaboration with the CSEM in Neuchâtel and under the guidance of its CEO Jean-Daniel Dubois, Vaucher Manufacture Fleurier has introduced an 8-day caliber whose regulating organ has been replaced with the new escapement without altering the caliber’s original size at all. To our great surprise and whilst still lacking long-term tests, the chronometric performance remained the same.

In other words, after the production phase, the first watches equipped with the new system may be slated in 3 years. Parmigiani Fleurier, a sister company owned by the same shareholder that owns the Sandoz Family Foundation, will be the first to retail them. It will, of course, be followed by other clients, most probably Hermès, which owns approximately 30% of the Vaucher Manufacture. This ingenious regulator may eventually even replace regulating organs of watches that cost less because they are produced in larger volumes. This is due to the inevitable quest for independence in the manufacture of mechanical watches.

A breakthrough

Until now, all the work carried out in silicon was limited to reproducing models in a material that had particularly appealing features. The manufacturing of its spring balance holds a secret exclusively known by the Swatch Group’s subsidiary company Nivarox; however, said secret has not been revealed to date. Indeed, we can more or less guess the components of its alloy but nowadays, except for Nivarox, no one can control a repetitive and regular production of a million pieces per year while guaranteeing the best quality. We can only admire and respect this. Sure enough, industrial excellence exists and it is more visible in mass production than in the niche of “Haute Horlogerie”.

Nevertheless, the fact remains that the progress made through the mastering of silicon has all been oriented towards the replacement of traditional balance-springs with silicon ones. It was a sort of “copy-and-paste” that the CSEM SA (Centre Suisse d’Electronique et de Microtechnique) made possible. Under a mandate of the Swiss Confederation, CSEM SA is a private organization that employs 400 workers in Neuchâtel. Its employees also work in MedTech and in the machinery and spatial industries. Further to this though CSEM SA has now become a cradle of research for the silicon balance-spring. Some current productions of prestigious brands such as Rolex, Patek Philippe, Groupe Richemont or Ulysse Nardin also start there.

Now, for the first time, the research conducted on this particular material has led to a breakthrough. As a retired researcher, Genequand devoted his newly found free time to a crazy dream, which was to use Flextex technologies in watchmaking. Usually, these feature in other applications on which he worked over the course of his career as a researcher and inventor. Put another way, Genequand wanted to bring to watchmaking his experience of applying attributes of free movement and friction of flexible articulations to precise mechanisms developed in the field of fiber-optic guidance and space mechanical projects. In a nutshell, he wanted to contribute a whole program.

The culmination of ten years work

Three key phases depict the new regulator’s ten years of preparation. The first one was introduced as a 20:1 scale model in 2004 and was on show in a hall in Neuchâtel and resembled a timeless relic similar to the functional Tinguely machines. After the presentation of this quite large prototype, CSEM decided to produce another model with a 5:1 scale, which was more compatible with watch sizes. Now, in 2014, the regulator is housed in an 8-day power reserve, a real watch caliber, which has been taken from the catalog of Vaucher Manufacture Fleurier.

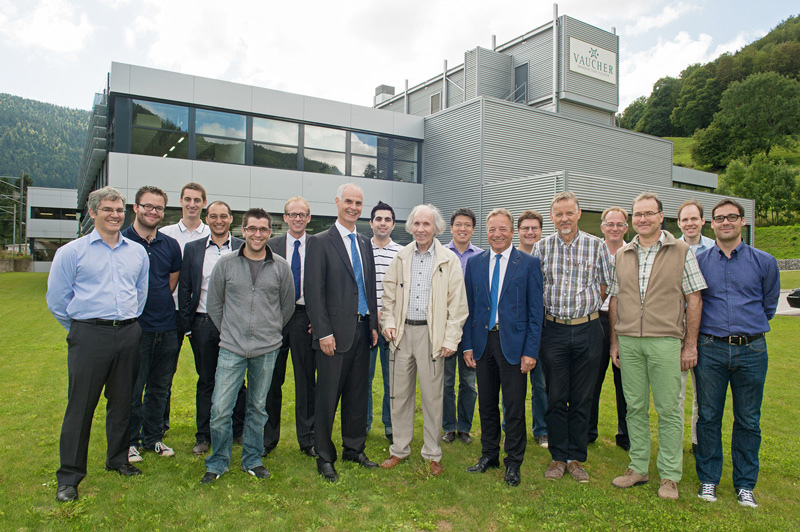

When Jean-Daniel Dubois was appointed head of the company and inherited this project, he was quite skeptical. However, the determination of his employees finally convinced him of its feasibility. He demanded that the new regulator bore the name of its inventor. It would take seeing the sparkle in Pierre Genequand’s eyes, present in Neuchâtel in front of the press and the technicians, to realize the extent to which this professional acknowledgement was significant to him. Of course, it absolutely did not affect his legendary humility.

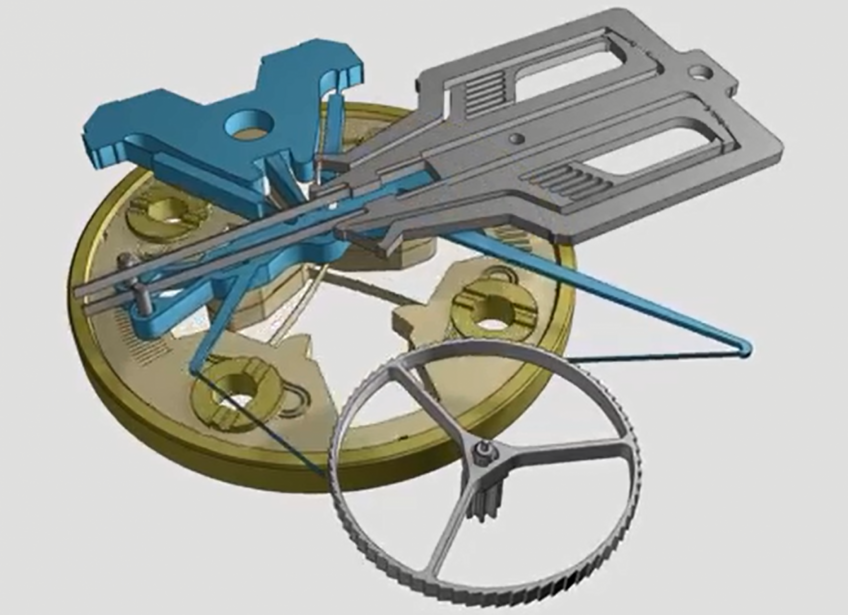

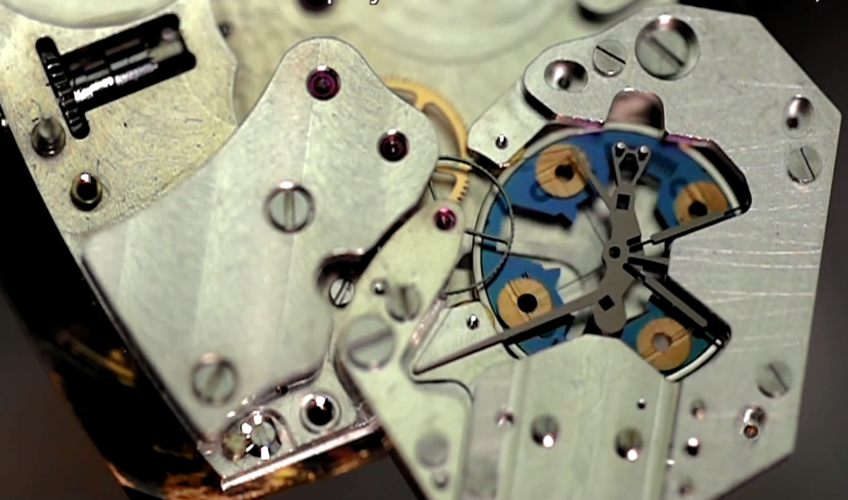

The Genequand system enables the wearer of a mechanical watch to only have to wind it once a month. It consists of three pieces: an isochronism compensator, a Wittrick oscillator and pallets.

Thanks to its 0.02-mm thick blades, it oscillates at 86,400 vibrations per hour, that is, at a frequency of 12.5 Hertz. It furthermore measures 10 x 15 mm. A team of twenty people worked on the execution of the project and It has shown how research, when conducted in an industrial context, can result into something promising. Its only drawback resides in the fact that the watch it will equip will not have a tick-tock sound and its seconds hand will give the impression that it is in a constant race instead of moving by 4 jumps a minute. It also bears a resemblance to the electrical watches that were famous for a while in the past or those which are still used in station halls. There are so many things yet to be invented… A tick-tock that is not the result of a shock between two components would be an example.

The power reserve: the end client is asking for more!

The “power reserve” argument has pervaded the rhetoric of Swiss watchmaking brands. It is a success on the market, as it is the proof that a movement’s efficiency can be improved and that it can also be controlled even in its most useful performances.

Indeed, what could be more practical than wearing a self-winding watch: one that automatically winds thanks to a rotor, and which has an oscillating mass that reacts to the wearer’s movements? And yet, when the watch is put in a corner, it stops after a while. This is inevitable as the watch is not moving but watchmakers are constantly working to increase the time it takes for the watch to stop after being removed from the wrist. When the watch is removed at the end of the working week, it should ideally be able to resume functioning without the wearer having to wind it on the Monday. Henceforth, the owner of a mechanical watch equipped with a Genequand regulator will easily go on holiday for weeks. That’s what we call revolutionary.

The official video of the Genequand system: