WEIGHTLESSNESS FOR THE BENEFIT OF WATCHMAKING RESEARCH

WEIGHTLESSNESS FOR THE BENEFIT OF WATCHMAKING RESEARCH

On September 22nd, H. Moser & Cie. and Precision Engineering AG took part in the first parabolic flight organised in Switzerland. With this event the two sister companies are the first to have carried out tests on movements and escapements in weightlessness and hyper-gravity, confirming them as pioneers in this field of watchmaking.

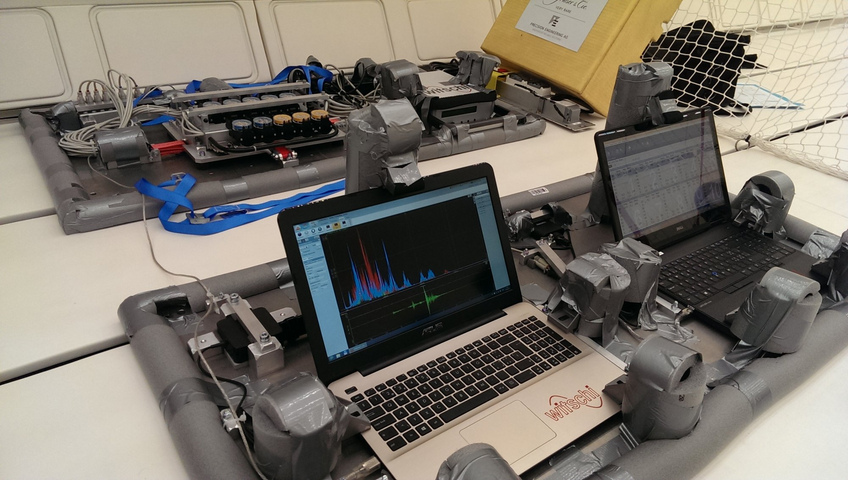

It is well known that Earth's gravity influences the operation of a mechanical watch, affecting the hairspring in particular, as well as other components such as the balance wheel. These influences can be estimated using theoretical models, but with multiple parameters it is impossible to perform perfect simulations. Edouard Meylan, CEO of H. Moser & Cie., explains: "Our aim is to compare various escapement configurations previously modelled on computers in an environment with limited mechanical constraints. This can only be achieved in a state of weightlessness." This is why the dynamic CEO decided to take part in the first parabolic flight organised in Dübendorf, Switzerland, on September 22nd. Using instruments specifically adapted by Witschi Electronics AG to perform tests in extreme conditions, Edouard Meylan, with the assistance of Johannes Mayr, an engineer from Witschi Electronics, measured the rate and amplitude achieved with various components. The solutions tested included different materials (e.g. paramagnetic) for escapement components – steel, nickel and ruby – each offering a distinct density and friction coefficient, different hairspring materials involving various degrees of rigidity, as well as hairsprings with alternative types of terminal curves, including flat end curves or a Phillips overcoil, as well as double hairsprings, to determine the influence of the end curve. An optical test with these components was also carried out on board the Airbus with the help of an observation test specially developed by the engineers from Precision Engineering.

This battery of tests enriches Precision Engineering’s overall research on regulating organs, which it has been carrying out for several years. As a specialist in escapement components, from the design and production to the final assembly of these high-quality products into the overall watch movement that it regulates, Precision Engineering is one of the few companies capable of defining and producing alloys for the creation of self- compensating hairsprings. CEO of the company, Dominique Lauper, points out: "With production of 50,000 regulating organs per year, Precision Engineering offers leading expertise not only in the manufacture and assembly of various components, but also in component design. The tests that we have conducted in zero- gravity enable us to determine the real effect of gravity on escapement components by carrying out comparative measurements under different conditions: zero gravity, normal terrestrial gravity and even hyper- gravity during the flight acceleration phases."

Edouard Meylan, CEO of H. Moser & Cie., with a movement in zero gravity

Edouard Meylan concluded: "The results we have obtained have exceeded our expectations and will allow us to confirm our theories. The tests performed will enable us to improve the stability and quality our chronometric performance and the isochronism of our timepieces. We have also been able to confirm new research directions, and we will capitalise on this by filing patents. These experiments are also the best example of Precision Engineering’s ability to provide clients with the most innovative and reliable solutions in terms of hairsprings and escapements."