Visit to Casio in Japan part 2: At Yamagata

The factory where Casio’s G-Shock watches are produced is in Yamagata, in the province of the same name, in the north of Japan’s main island Honshu.

Nothing suggests that these buildings may contain the many workshops where components, calibers and cases are produced and where caliber pieces are created by injection. The molds for press molding injections are also produced here. However, the assembly line for Premium calibers is unquestionably the most awe-inspiring aspect in these workshops. We just don’t know how they do it. Or rather, we think we do, but almost all of us lack real perspective: experiencing the production from the inside by following the assembly line in full. The rare and intricate craft requires the craftsmen’s full attention, as their task is to restock the machines with components, to monitor the sensors, the micro cameras lasers, and the feeler-spindles. They also make sure of the proper functioning of the optic testers that are used to verify that all the components that are fitted one by one at a very quick pace are positioned properly.

The visit teaches those who did not know a few things about these quartz watches. For example, that they are rigged with gear trains to display time. Or that micro motors propelled by both the quartz and a microprocessor drive the servo-controlled hands. In the words of the company director: “for us, this display mode is rather meant for high-end models such as the Edifices, the G-Shock Premium or the Oceanus series. Unfortunately these magnificent pieces are only sold in Japan.

Casio Premium: the luxury of hand-assembling

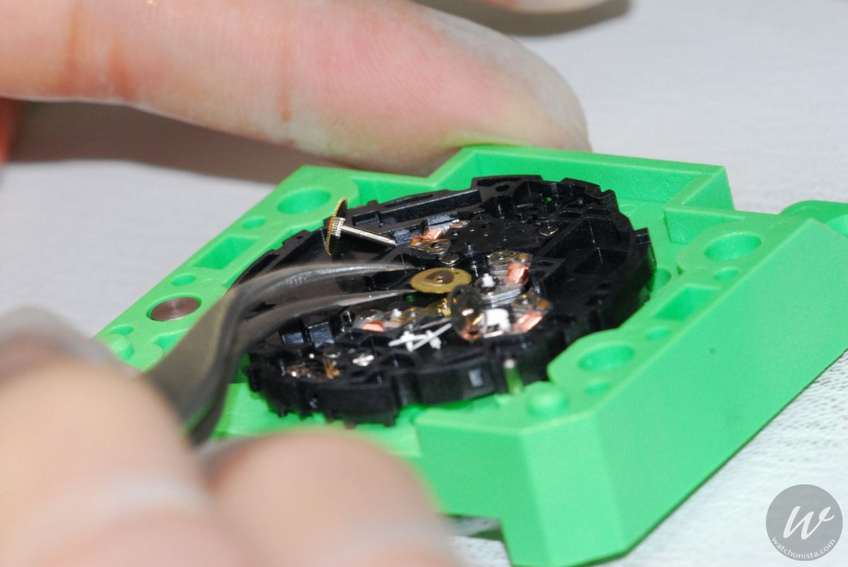

Yet the calibers used in the brand’s high end series are hand-assembled one by one by the manufacture’s best watchmakers, just as it happens with Swiss mechanical movements. Under the masks and overalls, it is not men, but the best women watchmakers who work in extremely difficult conditions. They work for as long as eight hours covered in their outfits and attached to their workshop space by antistatic straps. Their delicate and expert hands work on a series of movements with the help of powerful binocular magnifying glasses.

These movements are made mainly in resin and tare then tested and checked. Depending on the series – and in order to offer the most accurate time – the movements also feature either antennae to pick up the radio waves transmitted by atomic pendulums or micro GPS receivers. Some even have movement sensors to measure atmospheric pressure.

The women specialists also fit dials, some of which are embedded with solar sensors that equip the indestructible pieces to be autonomous. It is to be noted that some models also feature a “Smart Access” function. This system enables the watch to be configured via the crown, which gives access to different functions by turning or pressing it. These extremely intuitive and impressive pieces are seen on the wrists of all men and women in the field. That is one of the reasons why Casio is working on rejuvenating its products: in order to offer the highest quality finishes so watch owners feel proud of the watch they wear when in action.

This extremely robust range equips pilots of the RAF and huge numbers of action soldiers who know that these are tools that meet their requirements.

This is in fact something Casio emphasized: “This high-end collection, which was treated with the utmost care, is increasingly available in the best points of sale, where the most precious timepieces are sold. This is because aficionados of mechanical beauties are also aware of the limitations of their favorite watch. Thus, when they have to choose a watch to wear in their spare time, they buy the Japanese brand’s pieces”. These formidably efficient watches are equipped with new cases that the manufacture produced in stainless steel and resin. Beautiful, efficient and incredibly robust, the cases are produced in a material whose formula remains a secret and which allows them to absorb shock waves with ease to the extent that if a raw egg were hurled against them, it would not break.

Once they are assembled, the watches are tested again. Then, a strap is attached to the head – either a steel and resin strap or the new smooth, tear-proof carbon fiber strap.

The very masculine pieces are manageable and robust. We have seen them on the wrist of several men of action and they are absolutely indestructible. Today, a significant transition is underway with the upcoming new generation of G-Shock watches connected to Smartphones (Android or Apple) that will enable a 24/7 connection to the world.

Edifice Smartphone Link EQB-500

Multi-function

Bluetooth connection to Smartphone via “Casio Watch + Application”. The application allows all settings to be adjusted via the Smartphone’s dock

Solar function

Case in steel and Alphagel, a special absorbing material

Water resistant to 100 meters

Price: From € 299

--

First chapter of our visit to Casio: The home of the indestructible time