Contrôle Officiel suisse des Chronomètres (COSC)

There is no other institution in the world that is able to control, as per the international precision norm ISO 3159, such an amount of watch movements and industrial production.

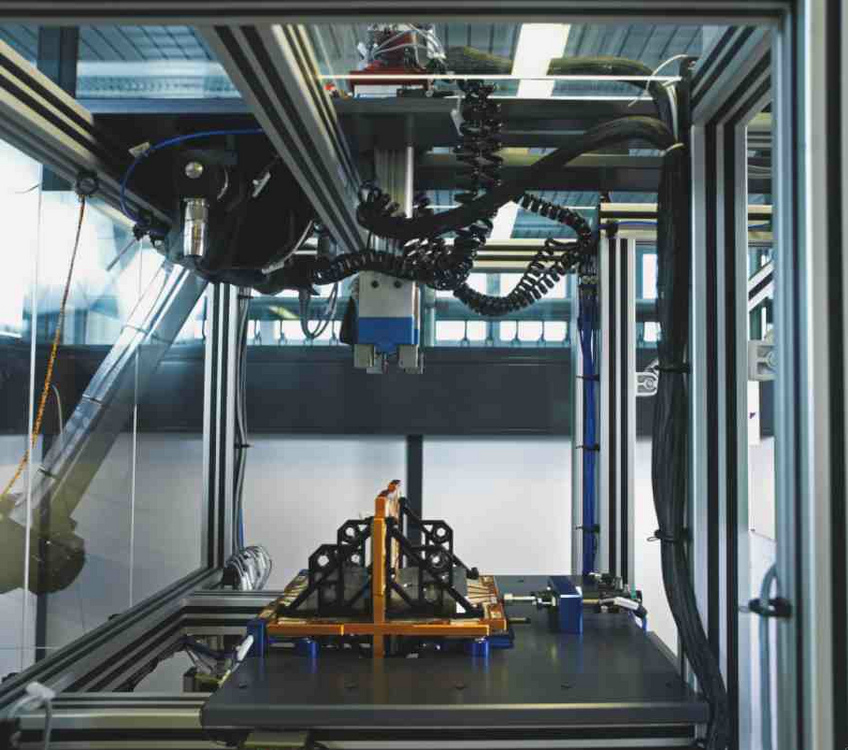

First of all, allow me to clarify that the COSC assesses mechanical watches according to the international norm ISO 3159. However, when it comes to assessing quartz watches and diver chronometers, internal instructions derived from this norm apply. The COSC is a non-profit association that manages high volumes thanks to exemplary automation and the special equipment developed by its engineers. The COSC’s aims are to make sure pieces meet all requirements in terms of precision, result traceability, measuring conditions and eventualities of an uninterrupted productivity.

Creation and Official Centers (BOs)

The COSC “Contrôle Officiel Suisse des Chronomètres” is a non-profit association which was created in 1973 by the Federation of the Swiss Watch Industry (FH) and five watchmaking districts (namely Geneva, Vaud, Neuchâtel, Bern and Solothurn). The aim was to unify their practices and their prices. The association is not subsidized, it is self-financed by its activities, it does not publish its annual budget but invests around CHF 1 million per year in improving its equipment and has around one hundred employees. When the COSC was created three former laboratories located in Bienne, Le Locle and Geneva (Timelab) became its BOs (short for “Bureaux Officiels de Contrôle de la marche des montres”). Their mission is to carry out chronometric tests and to issue chronometer certificates for third parties.

These offices are accredited SCS (Swiss Calibration Service) according to the ISO 17025 norm by the SAS (Swiss Accreditation Service). The SAS is the only Swiss authority empowered to award this accreditation on the basis of audits. Each BO can treat 30,000 to 40,000 movements per day and as the test lasts sixteen days – including Sundays and public holidays – these operations are uninterrupted.

All candidate movements must be submitted to the COSC’s premises, as carrying out tests elsewhere, for example in a manufacture, is strictly against the spirit of the association. Furthermore, only movements that meet the “Swiss Made” label criteria are eligible for tests.

The costs of precision

As the COSC is a non-profit association, test prices are very reasonable. Test fees are just over CHF30 per batch, irrespective of the number of movements. If only one piece is registered, then the price doesn’t even reach CHF10. This fee pays for a 16-day test in five positions and at three different temperatures ranging from eight to thirty-eight degrees.

As we can see, the price of the test is more than reasonable, but is that all? Actually, in order to calculate the final price to be awarded the chronometer certificate, we need to take into account the huge investments manufactures have to make beforehand in order to ensure their movements stand a chance. Take the example of an airline pilot like COSC’s former director Jean-Yves Soguel. It is not the actual examination that is expensive but the time and means invested to pass it.

Therefore, the cost of this certification is only a marginal percentage of the chronometer’s production cost. The COSC does not directly add value to the movements, but it provides scientific and official certification that the piece’s precision has been assessed and that the results shown are accurate.

In other words, it is the manufacture and not the COSC that pays the difference in cost price between a high-end movement and a chronometer. Everything else is just marketing and communication. However, in a field where brand individualism is the norm, a certification that grants undisputable acknowledgement by the general public and not only by expert collectors has a very bright future.

Refusing to be a brand

Having the “Chronomètre Suisse certifié” (certified Swiss chronometer) is an undeniable asset for final customers and therefore some brands systematically refer to it in their communication campaigns. The COSC label was registered in 2003 in class Nice 42. Why not register it in class 14, which is reserved to watch production? Surely it would have been better protected that way? The rational behind this is that this structure in service of watchmaking precision shuns being seen as a label or even a designation of origin (AOC) to avoid being seen as a competitor by its clients.

However, end customers consider the “Certified Swiss Chronometer” accreditation more than just a brand. Indeed, it is a word that has institutional ramifications even in Swiss law. Also, judging by the enthusiasm it has created since 2001 when the one millionth piece was registered, the COSC still deserves better promotion. The Confederation could just be the right actor for that, couldn’t it?

Entry Requirements

1.The representative must be a Swiss brand registered at a national intellectual property institute.

2. The movement must meet Swiss Made criteria, which means it must have been produced or bought, and assembled in Switzerland.

3. Each candidate movement must be physically deposited for a maximum of twenty-one days at one of the three BOs in full knowledge that under the ISO 3159 norm a series of compulsory tests must be carried out over a period of at least sixteen days, including one day for preparation.

4. According to an added clause in the COSC’s technical rules, a chronometer movement must present a permanent display of seconds.

5. Each submitted movement must belong to one of the following four categories: wristwatch with spring balance (1), pocket watch with spring balance (2), fixed timepiece (3, for example a marine chronometer), or quartz movement (4).

6. Movements must be subject to fifteen days of testing in five positions and at three temperatures(8° C, 23° C and 38°C): left crown, top crown, bottom crown, visible dial, back dial and verification of additional mechanisms’ functioning (that is, date, chronograph, and so on).

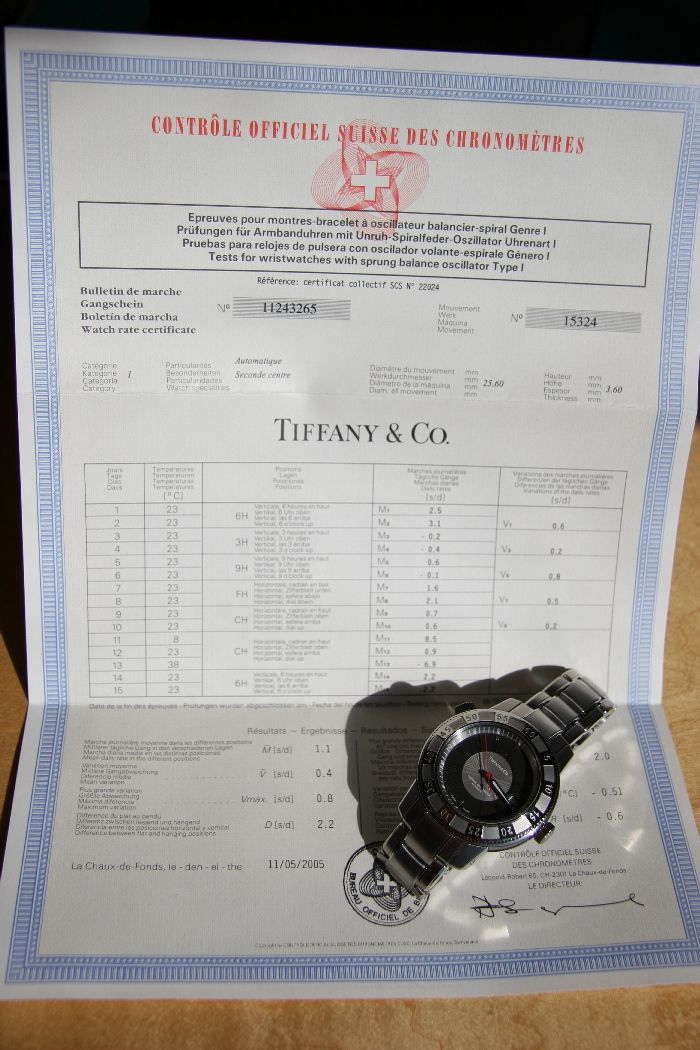

Conditions for certification (for mechanical movements)

Movements are measured and wound 24 hours a day, 365 days a year. This determines the rate difference between the drift of the sweep seconds in the candidate watch and a time reference delivered by a timeserver. The latter is composed of three atomic watches (2 set on rubidium GPS time and 1 set on internet time) and its residual error is inferior to 1 second in 300 years. The difference between the two consecutive states in 24 hours enables to establish the daily rate. This will later provide the basis on which the calculation of the seven criteria fixed by the norm can be carried out.

What are the contents of the norm’s text?

1. It is essential for a piece to meet seven criteria: average daily rate, mean variation in rates, greatest variation in rates, difference between rates in horizontal and vertical positions, largest difference in rates, thermal variation and rate-resumption.

2. Minimal requirements in seconds per day (s/d), category 1 (diameter of the movement less than 20 mm)

- average daily rate = -4 / +6

- mean variation in rates = 2

- greatest variation in rates = 5

- difference between rates in horizontal and vertical positions = -6 / +8

- largest difference in rates = 10

- thermal variation = ± 0.6

- rate-resumption = ± 5

3. Minimal requirements in seconds per day (s/d), category 2 (diameter of the movement equal or superior to 20 mm)

- average daily rate = -5 / +8

- mean variation in rates = 3.4

- greatest variation in rates = 7

- difference between rates in horizontal and vertical positions = -8 / +10

- largest difference in rates = 15

- thermal variation = ± 0.7

- rate-resumption = ± 6

4. Chronometer’s uniqueness: a serial number is engraved on the movement as a certification number will be given to the movement that passed the tests.

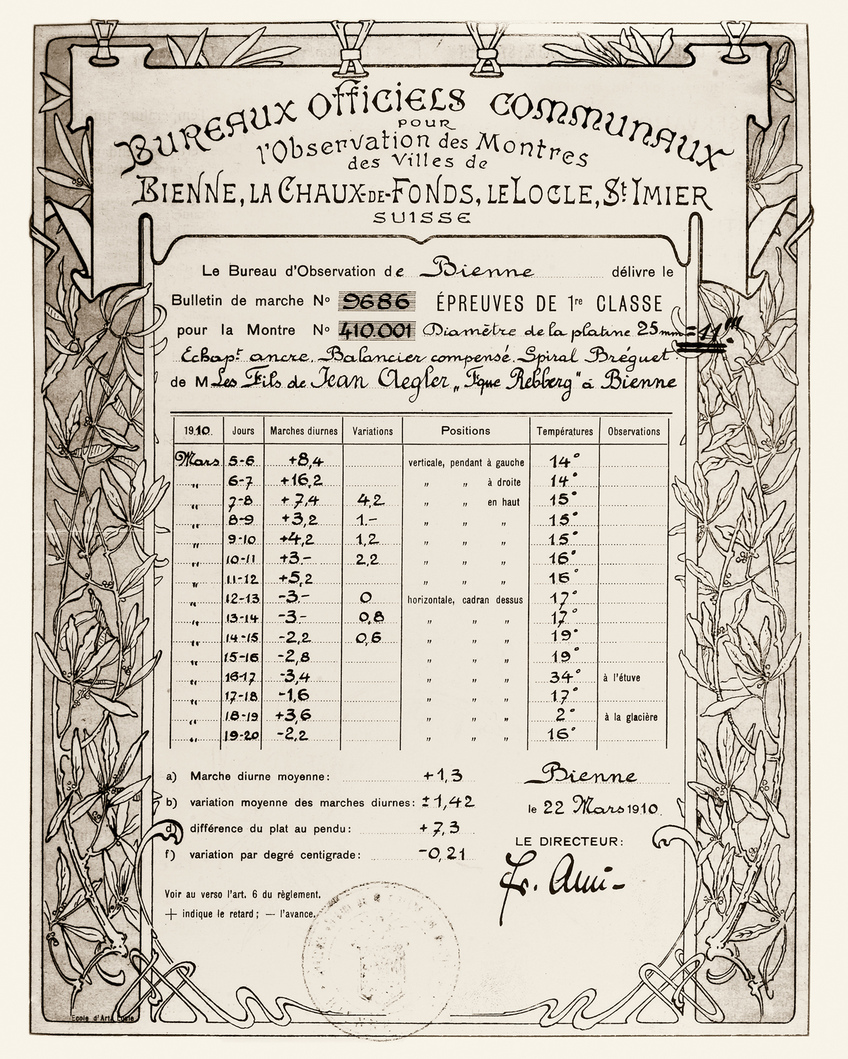

Before the COSC

By the end of the 19th Century, watchmakers felt the need to find a more official way of guaranteeing their watches’ precision. Thus, seven laboratories were created to verify and certify pieces. Even if the initiative stemmed from the corporate world, their implementation relied on horology schools. These institutions guaranteed indispensable neutrality and already had efficient tools at the service of the community as well as trained professionals. Furthermore, as they worked with their own students, they were remarkably flexible in terms of deadlines and schedules and this allowed for tests to be carried out uninterruptedly.

Not available to everyone

Contrary to former customs, watches can only be accredited by the COSC if both the case and the movement are Swiss Made. “The Board of Directors clearly reinstated it in 2010”, stated the COSC’s director Andreas Wyss. Thus movement suppliers must indicate to whom the units that are being submitted will be sent eventually. Furthermore, in order to avoid individuals presenting their pieces, the submitting Swiss brand must be registered at a national institute of intellectual property.

Not-so-secret numbers: very informative

As the COSC is a non-profit association, the publications of its general assembly reports and its annual reports are rich in information. For example, we can easily figure out the percentage of test fails. Let’s take the period of 2010-2013 when the increase in the amount of submitted movements reached 27.8%, that is, 1,631,252 movements accepted out of a total of 1,731,139 that had been submitted. Here, the fail rate was 5.8%.

In 2011, 52 brands submitted their movements to one of the COSC’s BOs. A total of 1,631,252 pieces received their chronometer certificate, which is 30% more than in 2010 (1,276,714). The amount of movements that failed was 99,887, which is 5.8% compared to 55,154 or 4.1% in 2010.

If we do a comparative going back several years, we can even figure out more sensitive information. Indeed, it is indirectly possible to estimate the amount of pieces produced by brands if we read between the lines. And so we see that the numbers vary and some brands get dangerously close to others in terms of production and others stagnate. In order to avoid any useless criticism despite the fact that these numbers are public, here are some considerations based on 2010’s numbers. Among the top-three submitting brands, Rolex was first with 751,285 pieces, followed by Omega with 509,301 and finally Breitling with 154,456 including 28,301 quartz pieces. As we all know, Rolex submits almost all of its production and Breitling publicly states that its whole production goes through the COSC. Thus, it is possible to have a very precise idea of data that none of these brands would accept to release. Get hold of previous statistics, for example those from 2011 to 2013, and you will be able to analyze the evolution in their production.

Within the highly interesting pages of 2010’s report, we find that unexpected names such as Enicar (17,115 pieces) or Mido (49,343) in front of Panerai, Chopard and Titoni (20,536). We also find forgotten brands such as Bremont (1,548 pieces), Normana (1,155) and Olma (1,047).

ILLEGAL? For the record, the term “chronometer” is considered “illegal” abroad. In other words, an institution similar to the COSC cannot use the term unless the movement has been subject to the tests as stipulated by the international norm ISO 3159. This enables the COSC to keep a kind of monopoly on watch precision.

OPINION. As far as the market is concerned, certain words engraved on a watch or in the pages of its history enhance its desirability: they give the piece an added value. Take the hallmarks: The Hallmark of Geneva or Geneva Seal is strict in terms of precision, aesthetics and geographical criteria. The label Qualité Fleurier hallmark is the newest but definitely the most successfully completed whereas the Snake hallmark, is linked to the Observatory in Besançon.

There are also very prized names for the oldest watches. The term “Observatory”, for instance, guarantees that the watch has its own “grade record” in terms of precision. The term “Competition Watch” means either that the watch participated in or won a chronometry prize and it particularly stirs collectors’ passions. Originally cast aside in this procession of prestigious words, the COSC is becoming more and more attractive each year. Less glamorous, neither a full label nor a brand that can generate money, the initials of the Contrôle Officiel Suisse des Chronomètres nevertheless contain genuine values –true door openers.

File published in the printed version of the JSH, Journal Suisse d'Horlogerie (April 2014)